ED copper foil is our main product. With the development of the communication and science technology, more and more ED copper foils are used for the electronic products manufacturing, such as Li-ion Battery, and Printed Circuit Board. Following the society demand, we master the latest and advanced production technology. Improve the copper foil performance, on the premise of quality assurance.

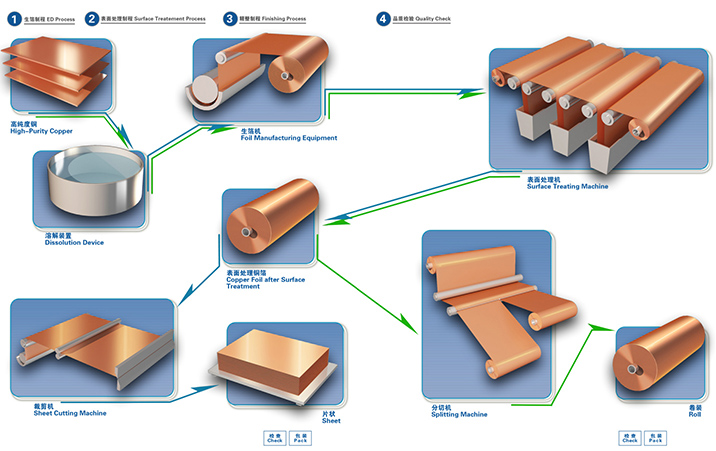

Producing Process

Dissolving:

Using high grade copper, selected for its purity and cleanliness, and dissolving it in acid to produce copper electrolyte solution. After that, the controlled induction of the chemical additives to the solution could make various mechanical properties of the base copper foils, thickness from 8um to 500um manufactured.

Plating-copper to Foil:

The electrolyte solution is pumped through filtering system into large plating tanks which consists partially immersed titanium drums, when meeting all chemical and quality standards. Each of them slowly rotates and is polarized against a conforming anode. When the drum rotating, a thin film of very pure copper is electrodeposited onto its surface. At this time, the drum side of the foil is smooth and shinny, and the other has a precisely controlled micro-crystalline structure with a matte appearance.

Surface Treating Process:

The rolls of the base foil, is now processed through a sequence of chemical and electro-chemical processing steps.

It is required to various electronic devices such as one surface and both surfaces roughening processing, fine roughening processing and black processing foils.

However, our technician also use resin system during laminations to enhanced its surface for wetting. After bonding treatment techniques, it ensures the integrity of adhesion to the dielectric substrate. This process apply processes apply protective chemical conversion coatings that prevent corrosion to both the shiny and matte surface during storage or lamination.

Quality Testing :

We use professional text equipment to do automatical visual inspection ensuring its consistent and peliable. After the foil has been treated, samples are cut from each roll and rigorously tested for quality.

Adhesive Coating:

If required, treatment foils can be coated with acrylic adhesives applied in our specially designed coating facility.

Slitting:

After a series of the manufacturing , it needs to be required by the quality control testes. The foils need to be taken to do the final inspection and slit to the precise widths and length to meet customer’s requirements.

Sheeting:

Processing to sheet products and guide bore processing for pin laminations are done. Going through inner process tests and reveiving final approval and certification, products which have passed the strict quality control are shipped as roll products or sheet products. Surely, various size of the copper sheet can be designed by our technicians to our customers.

You are here:

You are here: